EN ISO 12114

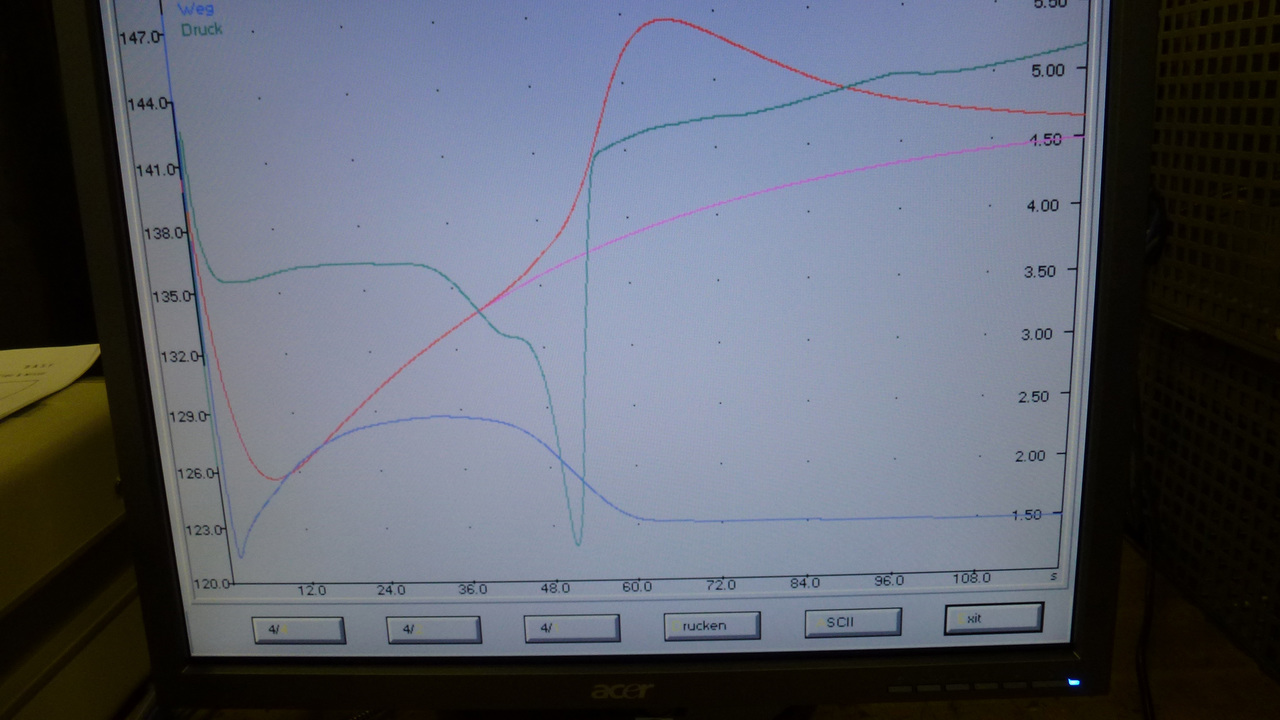

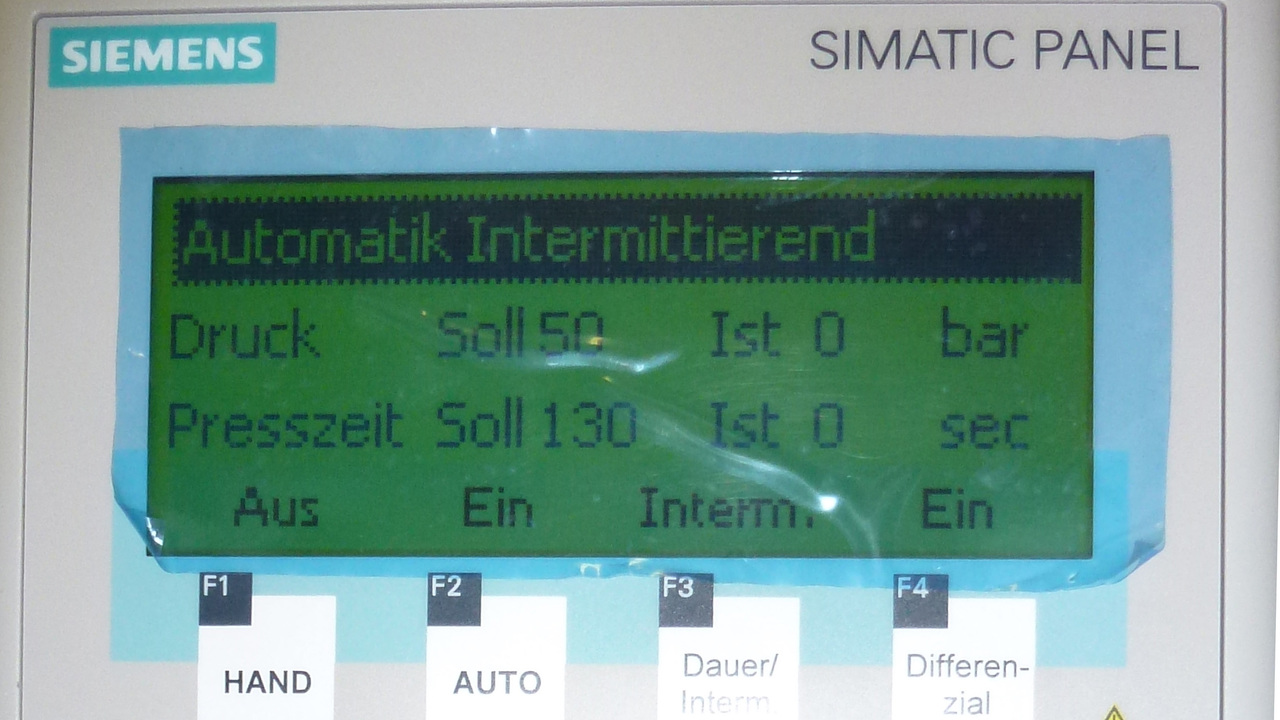

The REAKTOMETER test system is used to determine and analyse the reaction properties of thermosetting moulding materials like SMC, BMC and DMC. During the pressing process the temperature course of the material, the pressure, the displacement of the mould and optonally a dielectric and heat flux signal are measured and analysed. The usual parameters as temperature in the mould, pressure in the mould and the thickness of the test plate can be set and changed for the test. Therefore, with the assistance of a series of measurements, it ispossible to determine the influence of these parameters. The REAKTOMETER is equipped with an easy to use PC system for the evaluation and documentation of the data.

The evaluation of the test results with the REAKTOMETER is used for the characterization of a moulding material or prepreg, for the compound development, for comparing different types of material with one another, for production control, determination of processing and observing of the material over a period of time (conditioning and aging control). Furthermore it is possible to define the influence of various components, such as curing agents, inhibitors, LP additives, fillers etc. during compound development.

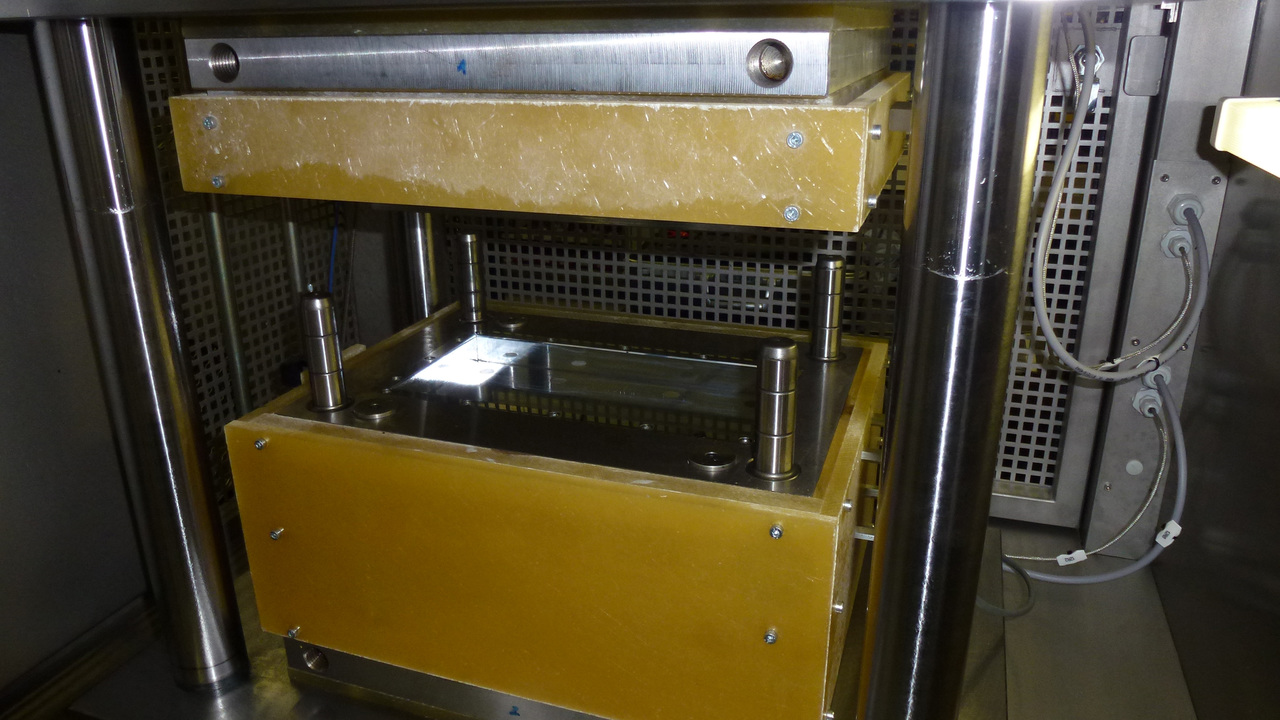

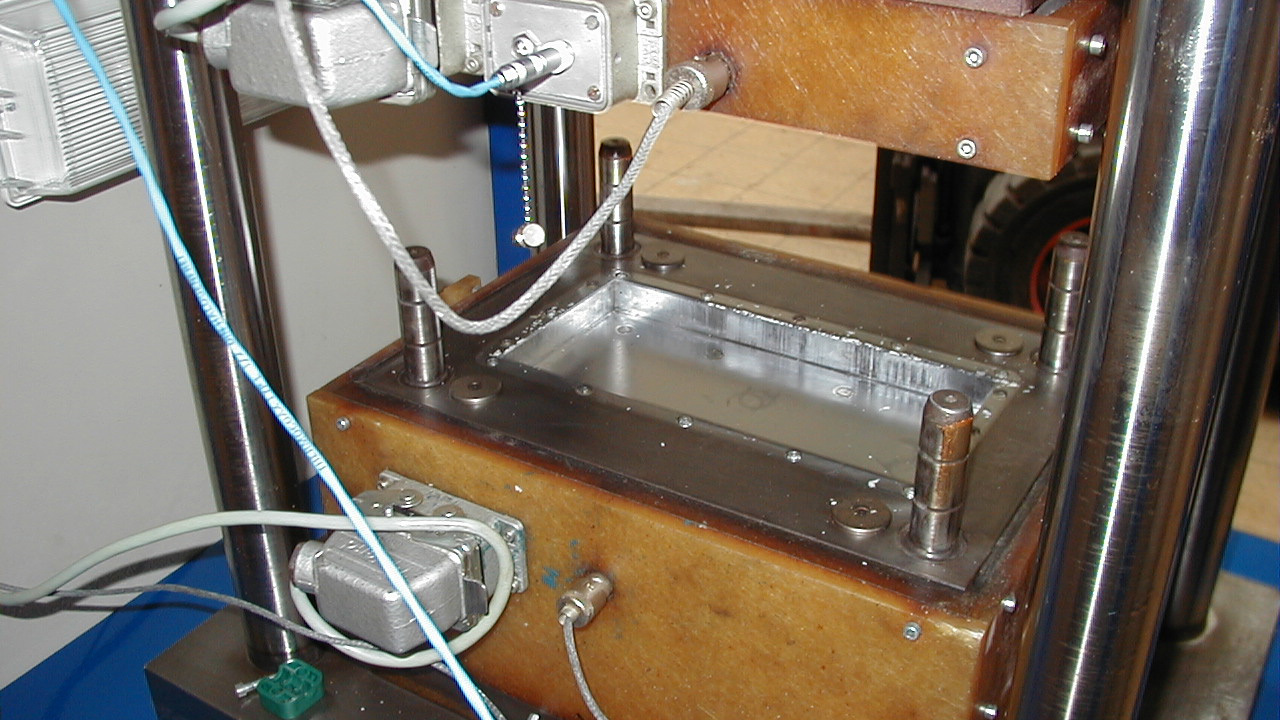

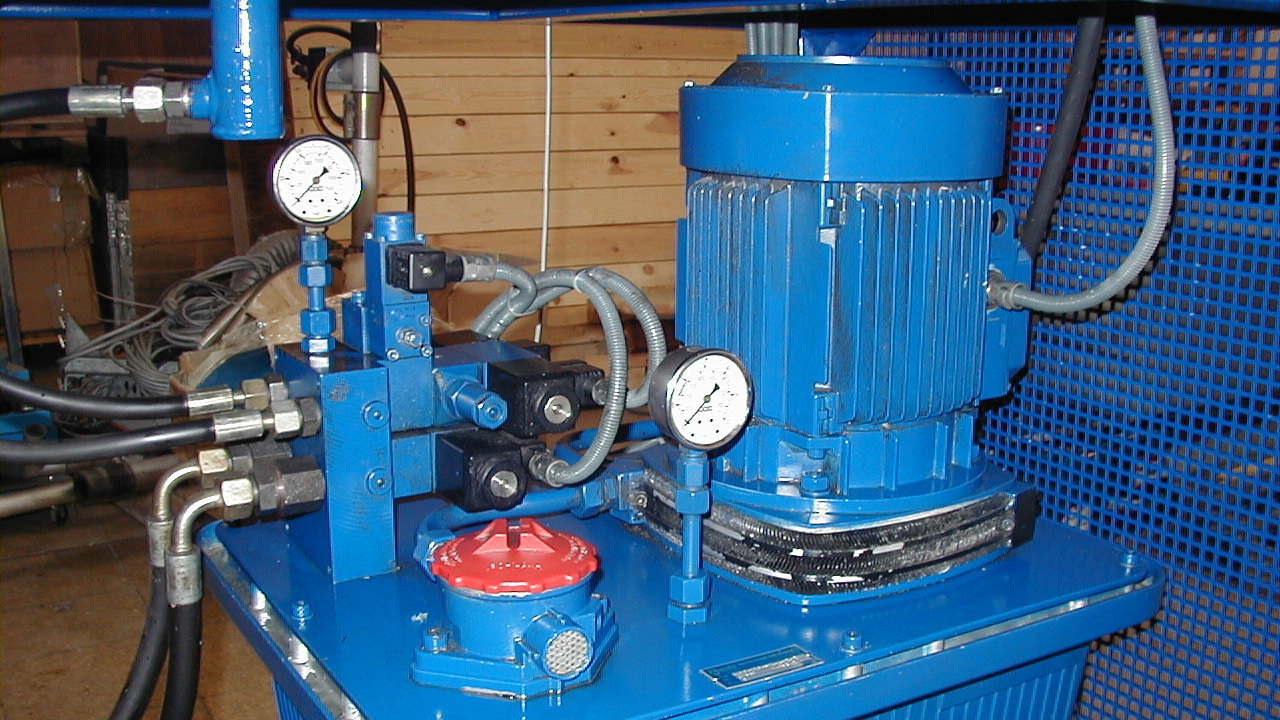

The press is built as a hydraulical table top press with 4-column guiding and upper stroke cylinder. The hydraulic works with a twin pump (fast movement->low pressure, slow movement -> high pressure). Switching is done by contact free position switches. The closing force is max 360 kN.

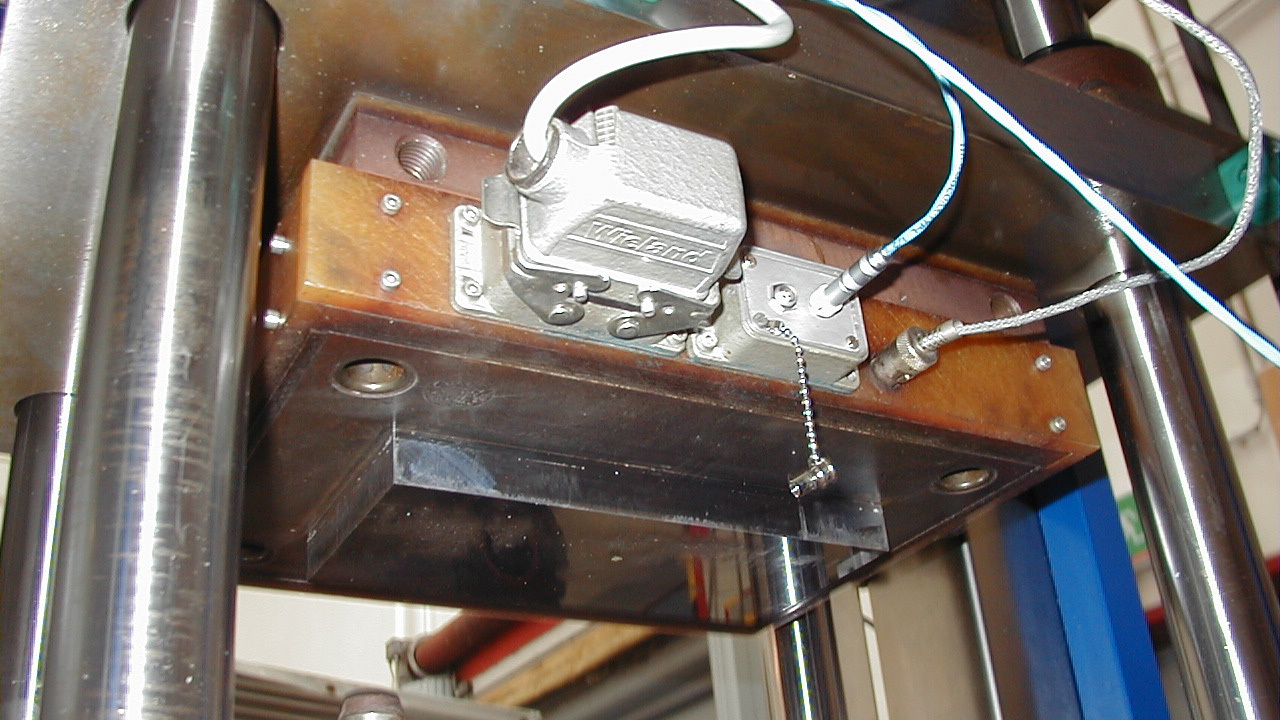

The REAKTOMETER is a plate mould for rectangular test plates of size 120 mm x 250 mm. The mould has shear edges, the surface is chrome plated and the core is polished. The plate thickness can be varied in the range of 0.7 mm through ca.17 mm by the amount of the compound used. Mould heating is done with electrical cartridges. The mould is insulated at all outer surfaces. Each half of the mould is connected to a separate temperature controller and has a removable temperature sensor PT 100.

The REAKTOMETER is an important instrument for setting up a quality management according to standard ISO 9000 ff.